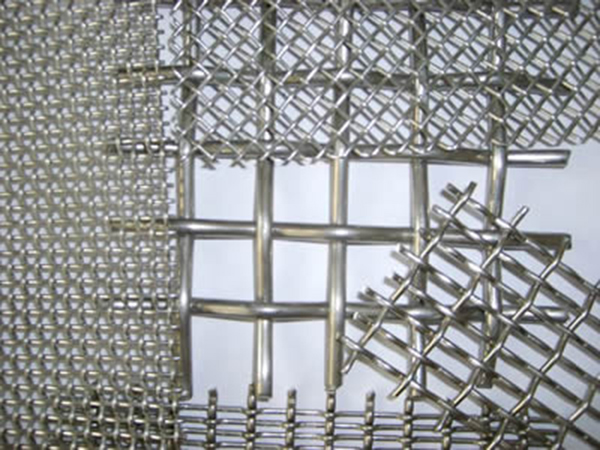

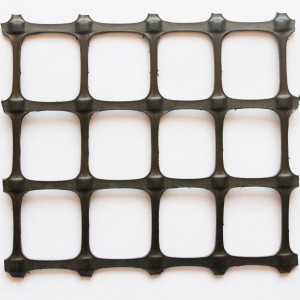

Crimped Wire Mesh For Industry

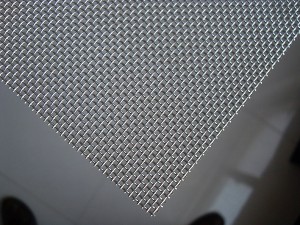

Black wire, spring steel wire, manganese steel wire and stainless steel wire.

High tensile screen cloth is commonly used in heavy duty applications for scalping and sizing of rocks, aggregates, limestone, etc.

They are weaved in sizes to suite most vibrating screens and available in:

* High Tensile Steel---Abrasion resistance

* Stainless Steel---Corrosion resistance

* Monel, Brass, etc---General applications

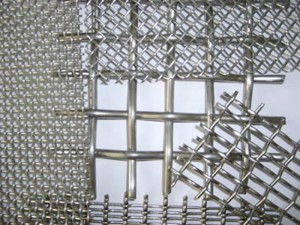

Crimped Wire Mesh is made through crimping mesh machine with pre-crimped wire in the following styles listed. Square or rectangular openings available due to the different crimping styles: Arch crimp weave; Double lock weave; Drake cloth; Flat top; Hi-ton weave; Hollander weave; Intermediate Crimp weave; Long slot; Multi-strand weave; Plain weave; Ribbon mesh in plain weave; Square mesh weave; Twill weave.

1.Flat top crimped, also called pressed crimped, is made from round and profiled plain weave wire. All the mesh knuckles is being on the underside. The structure is very heavy and durable. The smooth surface is the characteristic of the weaving method. This structure can allow the materials to move more freely over the screen. It is widely used in the vibrating screen.

2.Lock crimped is a refinement of the intermediate crimped. It can lock the wire at their position through pressed at each side of the raised wire. This structure can add the stability of the crimped woven wire mesh.

3.Intermediate crimped can be divided into single intermediate crimped and double intermediate crimped.

The single intermediate crimped means the weft wire is pre-crimped and the warp wire is directly woven. The double intermediate crimped means both the weft wire and warp wire is pre-crimped and then woven together.

4.Double crimped is also called plain weave. Different from the intermediate crimped, both the warp wire and weft wire are woven directly by straight wire. We can get a rigid construction through evenly crimp in warp and weft wire. This is used mainly with lighter wires to ensure tension in a light screen.

| Aperture mm | Aperture Tolerance mm | Wire mm | Edge Length mm | Weight kg/m2 | ||

| Minimum | Maximum | Minimum | Maximum | |||

| 101.60 | 98.55 | 104.65 | 12.70 | 12.70 | 50.80 | 17.92 |

| 88.90 | 86.23 | 91.57 | 12.70 | 12.70 | 44.45 | 20.16 |

| 76.20 | 73.91 | 78.49 | 12.70 | 12.70 | 38.10 | 23.04 |

| 63.50 | 61.60 | 65.41 | 12.70 | 12.70 | 31.75 | 26.88 |

| 63.50 | 61.60 | 65.41 | 9.19 | 9.19 | 31.75 | 14.76 |

| 57.15 | 55.44 | 58.86 | 9.19 | 9.19 | 28.58 | 16.17 |

| 50.80 | 49.28 | 52.32 | 12.70 | 12.70 | 25.40 | 32.26 |

| 50.80 | 49.28 | 52.32 | 11.10 | 11.10 | 25.40 | 25.28 |

| 50.80 | 49.28 | 52.32 | 9.19 | 11.10 | 25.40 | 17.88 |

| 50.80 | 49.28 | 52.32 | 7.92 | 7.92 | 25.40 | 13.57 |

| 44.45 | 43.12 | 45.78 | 9.19 | 9.19 | 22.23 | 20.00 |

| 44.45 | 43.12 | 45.78 | 7.92 | 7.92 | 22.23 | 15.21 |

| 41.28 | 40.04 | 42.51 | 9.19 | 9.19 | 20.64 | 21.25 |

| 41.28 | 40.04 | 42.51 | 7.92 | 7.92 | 20.64 | 16.19 |

| 38.10 | 36.69 | 39.24 | 9.19 | 9.19 | 19.05 | 22.68 |

| 38.10 | 36.69 | 39.24 | 7.92 | 7.92 | 19.05 | 17.31 |

| 38.10 | 36.69 | 39.24 | 7.19 | 7.19 | 19.05 | 14.49 |

| 31.75 | 30.80 | 32.70 | 9.19 | 9.19 | 15.88 | 26.20 |

| 31.75 | 30.80 | 32.70 | 7.92 | 7.92 | 15.88 | 20.08 |

| 31.75 | 30.80 | 32.70 | 7.19 | 7.19 | 15.88 | 16.85 |

| 28.58 | 27.72 | 29.43 | 7.92 | 7.92 | 14.29 | 21.83 |

| 28.58 | 27.72 | 29.43 | 7.19 | 7.19 | 14.29 | 18.35 |

| 25.40 | 24.64 | 26.16 | 7.92 | 7.92 | 12.70 | 23.91 |

| 25.40 | 24.64 | 26.16 | 7.19 | 7.19 | 12.70 | 20.14 |

| 19.05 | 18.48 | 19.62 | 5.72 | 5.72 | 9.53 | 16.78 |

| 15.88 | 15.40 | 16.35 | 4.50 | 4.50 | 7.94 | 12.62 |

| 11.00 | 10.67 | 11.33 | 4.00 | 4.00 | 5.50 | 13.55 |

| 10.00 | 9.70 | 10.03 | 4.00 | 4.00 | 5.00 | 14.51 |

| 8.00 | 7.76 | 8.24 | 4.00 | 4.00 | 4.00 | 16.93 |

| 6.35 | 6.16 | 6.54 | 2.67 | 2.67 | 3.18 | 10.04 |

| 6.30 | 6.11 | 6.49 | 2.50 | 2.50 | 3.15 | 9.93 |

| 4.00 | 3.88 | 4.12 | 2.00 | 2.00 | 2.00 | 9.31 |

| 3.00 | 2.91 | 3.09 | 2.00 | 2.00 | 2.00 | 11.17 |

| 2.00 | 1.94 | 2.06 | 1.50 | 1.50 | 1.50 | 8.99 |

1)The wire crimped wire mesh is composed of iron wire and black iron wire. It has the characteristics of beautiful structure and strong durability, and wire crimped wire is used for mining, coal, construction, petrochemical, construction machinery and so on.

2) Galvanized ginning network has a variety of materials, widely used in mining, petroleum, chemical, construction, machinery accessories, protective net, packaging network, barbecue net, vibration screen, food machinery network, highway, railway, infrastructure ,etc.

3) Stainless steel ginning network is mainly used for food, mining, chemical, pharmaceutical, petroleum, metallurgy, machinery, protection, construction, handicrafts and other industries.

4) Crimped wire mesh panel structure beautiful, durable, and more used in mining, coal plants, construction, petrochemical, construction machinery and other places