Featured

Featured

-

Wholesale China Welded Mesh Reinforcement Manufacturers Suppliers – Welded Wire Mesh Panel Sheet – Chongguan

Low carbon steel wire(Q195,Q235), stainless steel wire • Black welded mesh panel (paint oil) without any surface treatment. • Electrical galvanized before/after welding (Electric galvanized welded mesh panel) • Hot deep galvanized before/after welding (hot deep galvanized welded mesh panel) • PVC coated welded mesh panel • PVC Powder painted mesh panel 1. Galvanized Welded Mesh Panels offer excellent characteristics such as corrosion resistance, oxidation resistance, acid resistance, alkali r... -

Wholesale China Temporary Garden Fence Factories Pricelist – High Security 358 Mesh Fence – Chongguan

Panels Post Fence Panel Size Post Size Post Height Total Number of Fixings Height Height/Width Length/Width/Thickness Inters- 1 clamp Corners-2 clamp m mm mm mm 2.0 2007 × 2515 60×60×2.5mm 2700 7 14 2.4 2400 × 2515 60×60×2.5mm 3100 9 18 3.0 2997 × 2515 80×80×2.5mm 3800 11 22 3.3 3302 × 2515 80×80×2.5mm 4200 12 24 3.6 3607 × 2515 100×60×3mm 4500 13 26 3.6 3607 × 2515 100×1... -

Wholesale China Mesh Fence And Gate Exporters Companies – Bouble Wire Fence for Landscaping – Chongguan

The special specifications are available on request. Double Wire Fence Height × Width Panel mm Mesh Size mm Wire Diameter Post of Height mm Wire Dia mm Wire Dia mm Wire Dia mm 630×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1100 830×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1300 1030×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1500 1230×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1700 1430×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1900 ... -

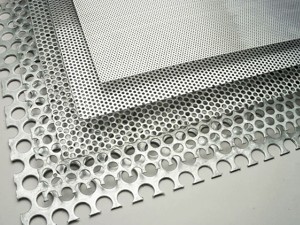

Wholesale China 304 Stainless Steel Wire Mesh Exporters Companies – Perforated Metal Mesh Sheet with Various Hole – Chongguan

Stainless Steel SUS 304 and 316, Galvanized Steel, Carbon Steel, Aluminum, and all types of metals. Round, square, long round, triangle, scale, diamond, oval, hexangular, slot etc. In general it is advisable to use a hole size larger than the material thickness. The closer the hole size and material thickness come to a 1 to 1 ratio, the more difficult and expensive the process is. Dependent on the material type, smaller hole size to material ratios can be achieved.The minimum diameter we can... -

Wholesale China Hydraulic Pressure Filter Exporters Companies – Cost Effective Filter Basket Material – Chongguan

Stainless steel mesh filter basket 1.Material: Stainless steel mesh, steel mesh, copper mesh, black wire mesh etc 2.Mesh count: 2-3200mesh 3.Wire diameter: 0.018-2.5mm 4.Size: 10mm-300mm 5.Shapes: Round shape, rectangular shape, toroidal shape, square shape, oval shape, other special shape 6.Layer: Single layer, multi-layers Perforated metal filter basket 1.Material: Stainless Steel,cast iron,carbon steel,etc. 2.Type: Standard filter basket and slanted filter basket. 3.Filer media: perforatio... -

Wholesale China Perforated Filter Tube Company Products – Pleated Filter of Large Filter Area – Chongguan

• Material: SS304, SS316, stainless steel woven wire mesh, stainless steel sintered fiber felt. • Filter rating: 0.1 micron to 100 micron. • Inner diameter: 28 mm, 40 mm. • Outer diameter: 64 mm, 70 mm. • Length: 10″, 20″, 30″, 40″. • Operating temperature: -200 – 600℃. • Low capital cost. • High porosity and good air permeability. • High dirt holding capacity. • Long service life time. • High temperature resistance. • Made entirely of SS304 or SS316, cleanable a... -

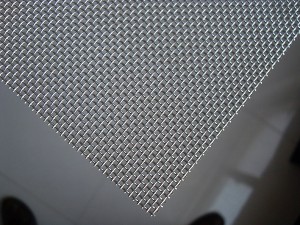

Wholesale China Coated Wire Mesh Factory Quotes – Stainless Steel Woven Wire Mesh Netting CLoth – Chongguan

Material: SS 201, SS304, SS304L, SS316, SS316L, SS321, SS347,SS430, Monel. Type 304 Often referred to as “18-8″ (18% chromium, 8% nickel) T-304 is the basic stainless alloy most commonly utilized for wire cloth weaving. It withstands outdoor exposure without rusting and resists oxidation at an elevated temperature up to 1400 Degrees Fahrenheit. Type 304 L Type 304 L is very similar to T-304, the difference being the reduced carbon content for better weaving and secondary welding c... -

Wholesale China Galvanised Weld Mesh Panels Manufacturers Suppliers – Steel Grating For Stairs and Walkway – Chongguan

As producing method: 1.Welded steel grating 2.Press-locked grating 3.Swage-locked grating 4.Riveted grating 5.Offshore Platform Reinforced Floor Grating As material: 1.Aluminum grating 2.Stainless steel grating 3.Expanded Steel Grating 4.Fiberglass grating No. Item Description 1 Bearing Bar Size 25×3, 25×4, 25×4.5, 25×5, 30×3, 30×4, 30×4.5, 30×5, 32×5, 40×5, 50×5, 65×5, 75×6, 75×10—100x10mm etc. I bar: 25x5x3... -

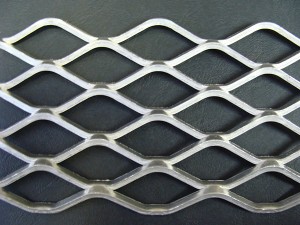

Wholesale China 304 Stainless Steel Mesh Quotes Pricelist – Stronger Expanded Metal Mesh Sheet – Chongguan

Made by slitting and stretching metal sheets to create diamond-shaped openings, Expanded Metal forms screens, window security panels and machine guards to name a few applications for this practical and versatile product line. In the decorative version of the product, shelving, signage, and ceiling tiles are among the most popular applications. Expanded Metal is supplied in a Standard (Raised) diamond pattern or a Flattened diamond pattern. Grating and Catwalk Expanded Metals are also part of ... -

Wholesale China Welded Mesh Types Quotes Pricelist – Galvanized Welded Wire Mesh – Chongguan

Mesh Size Wire Gauge Diameter In mm In Inch BWG No. MM 6.4mm 1/4Inch BWG24-22 0.56mm- 0.71mm 9.5mm 3/8Inch BWG23-19 0.64mm – 1.07mm 12.7mm 1/2Inch BWG22-16 0.71mm – 1.65mm 15.9mm 5/8Inch BWG21-16 0.81mm – 1.65mm 19.1mm 3/4Inch BWG21-16 0.81mm – 1.85mm 25.4x 12.7mm 1 x 1/2Inch BWG21-16 0.81mm – 1.85mm 25.4mm 1Inch BWG21-14 0.81mm – 2.11mm 38.1mm 1 1/2Inch BWG19-14 ... -

Wholesale China Welded Iron Mesh Factories Pricelist – Galvanized Welded Wire Mesh – Chongguan

Mesh Size Wire Gauge Diameter In mm In Inch BWG No. MM 6.4mm 1/4Inch BWG24-22 0.56mm- 0.71mm 9.5mm 3/8Inch BWG23-19 0.64mm – 1.07mm 12.7mm 1/2Inch BWG22-16 0.71mm – 1.65mm 15.9mm 5/8Inch BWG21-16 0.81mm – 1.65mm 19.1mm 3/4Inch BWG21-16 0.81mm – 1.85mm 25.4x 12.7mm 1 x 1/2Inch BWG21-16 0.81mm – 1.85mm 25.4mm 1Inch BWG21-14 0.81mm – 2.11mm 38.1mm 1 1/2Inch BWG19-14 ... -

Wholesale China Black Annealed Wire Quotes Pricelist – Galvanized Wire Made In China – Chongguan

Electro galvanised wire (cold galvanized wire) is made by means of wire drawing followed by heat treatment and electro galvanizing. The galvanizing is made with mild steel or carbon steel wire in the plating bath, through the electric current unipolarity making zinc plating gradually on the surface. The galvanizing speed is slow to ensure a uniform coating, with thin thickness, usually only 3 to 15 microns. The outward appearance of electro galvanised steel wire is bright, the corrosion resis...