Featured

Featured

-

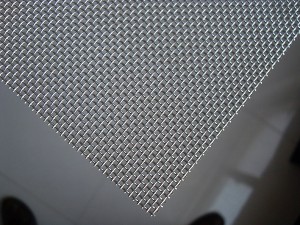

Wholesale China Wire Mesh Panels For Concrete Factory Quotes – Most Durable Aluminium Window Screen – Chongguan

Aluminum window screen is made of Al-Mg alloy wire in plain weaving. Screens made from aluminum mesh is one of the sturdiest and most durable screens available. They have a long lifespan and will protect you from different weather conditions, including rain, strong winds, and even hail in some cases. Aluminum mesh screens are resistant to abrasion, corrosion, and rust, making them a great screen choice for nearly any environment. Aluminum wire window screens also will not sag or rust, extend... -

Wholesale China Fence Company China Company Products – High Security 358 Mesh Fence – Chongguan

Panels Post Fence Panel Size Post Size Post Height Total Number of Fixings Height Height/Width Length/Width/Thickness Inters- 1 clamp Corners-2 clamp m mm mm mm 2.0 2007 × 2515 60×60×2.5mm 2700 7 14 2.4 2400 × 2515 60×60×2.5mm 3100 9 18 3.0 2997 × 2515 80×80×2.5mm 3800 11 22 3.3 3302 × 2515 80×80×2.5mm 4200 12 24 3.6 3607 × 2515 100×60×3mm 4500 13 26 3.6 3607 × 2515 100×1... -

Wholesale China Wire For Fencing Company Products – Black Annealed Low Carbon Steel Wire – Chongguan

The annealing process is used to achieve a finished product from low carbon steel wire. Annealing involves heating the wire to a specific temperature before cooling it at a prescribed rate in order to achieve the desired result.Annealing is used with the goal of increasing the ductility of the wire and reducing the hardness. This allows the wire to be flexible while still remaining durable. With these properties, annealed wire is self-tying and can stay in place when wrapped around itself. M... -

Wholesale China Wire Mesh Industries Factory Quotes – Stainless Steel Woven Wire Mesh Netting CLoth – Chongguan

Material: SS 201, SS304, SS304L, SS316, SS316L, SS321, SS347,SS430, Monel. Type 304 Often referred to as “18-8″ (18% chromium, 8% nickel) T-304 is the basic stainless alloy most commonly utilized for wire cloth weaving. It withstands outdoor exposure without rusting and resists oxidation at an elevated temperature up to 1400 Degrees Fahrenheit. Type 304 L Type 304 L is very similar to T-304, the difference being the reduced carbon content for better weaving and secondary welding c... -

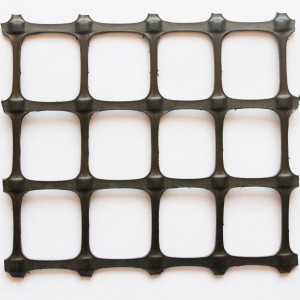

Wholesale China Galvanised Steel Mesh Panels Factories Pricelist – High Strength Biaxial Plastic Geogrid – Chongguan

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine. Index Properties Test Method Unit GG1515 GG2020 GG3030 GG4040 MD TD MD TD MD TD MD TD Polymer – – PP PP PP PP Minimum Carbon Black ASTM D 4218 % 2 2 2 2 Tensile Strength@ 2% Strain ASTM D 6637 Kn/m 5 5 7 7 10.5 10.5 14 14 Tensile Strength@ 5% Strain ASTM D 6637 Kn/m 7 7 14 14 21 21 28 2... -

Wholesale China Hydraulic Filter Base Quotes Pricelist – Cost Effective Filter Basket Material – Chongguan

Stainless steel mesh filter basket 1.Material: Stainless steel mesh, steel mesh, copper mesh, black wire mesh etc 2.Mesh count: 2-3200mesh 3.Wire diameter: 0.018-2.5mm 4.Size: 10mm-300mm 5.Shapes: Round shape, rectangular shape, toroidal shape, square shape, oval shape, other special shape 6.Layer: Single layer, multi-layers Perforated metal filter basket 1.Material: Stainless Steel,cast iron,carbon steel,etc. 2.Type: Standard filter basket and slanted filter basket. 3.Filer media: perforatio... -

Wholesale China Twin Loop Wire Binding Quotes Pricelist – Black Annealed Low Carbon Steel Wire – Chongguan

The annealing process is used to achieve a finished product from low carbon steel wire. Annealing involves heating the wire to a specific temperature before cooling it at a prescribed rate in order to achieve the desired result.Annealing is used with the goal of increasing the ductility of the wire and reducing the hardness. This allows the wire to be flexible while still remaining durable. With these properties, annealed wire is self-tying and can stay in place when wrapped around itself. M... -

Wholesale China Fence Post Exporters Companies – Barbed Wire For Fencing System – Chongguan

Barbed Wire Specification Type Wire Gauge (BWG) Barb distance (cm) Barb length (cm) Electric GalvanizedBarbed wire ; Hot-dip Galvanized Barbed Wire 10# x12# 7.5-15 1.5-3 12# x12# 12# x14# 14# x 14# 14# x16# 16# x16# 16# x18# Pvc Coated Barbed Wire Before coating after coating 1.0mm-3.5mm 1.4mm-4.0mm BWG11#-20# BWG8#-17# SWG11#-20# SWG8#-17# PVC coating thickness: 0.4mm-1.0mmDifferent colors or length are available as customers` request Gauge of Approx... -

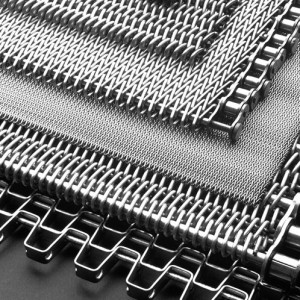

Stainless Steel Wire Mesh Conveyor Belt – Chongguan

Flat wire conveyor belts have two types according to its loading capacity. One is Standard Duty General Purpose flat wire belt, another is Heavy Duty Belt. All flat wire belting offers a smooth conveying surface and a maximum open area for free air flow or water drainage. They are easy to clean and are extremely sanitary, especially when manufactured with high quality clinched edges. Clinched-edge treatment of these belts results in a number of additional user benefits including keeping the t... -

Wholesale China Pvc Coated Welded Mesh Company Products – Welded Wire Mesh Panel Sheet – Chongguan

Low carbon steel wire(Q195,Q235), stainless steel wire • Black welded mesh panel (paint oil) without any surface treatment. • Electrical galvanized before/after welding (Electric galvanized welded mesh panel) • Hot deep galvanized before/after welding (hot deep galvanized welded mesh panel) • PVC coated welded mesh panel • PVC Powder painted mesh panel 1. Galvanized Welded Mesh Panels offer excellent characteristics such as corrosion resistance, oxidation resistance, acid resistance, alkali r... -

Wholesale China Cut Wire Factories Pricelist – Galvanized Wire Made In China – Chongguan

Electro galvanised wire (cold galvanized wire) is made by means of wire drawing followed by heat treatment and electro galvanizing. The galvanizing is made with mild steel or carbon steel wire in the plating bath, through the electric current unipolarity making zinc plating gradually on the surface. The galvanizing speed is slow to ensure a uniform coating, with thin thickness, usually only 3 to 15 microns. The outward appearance of electro galvanised steel wire is bright, the corrosion resis... -

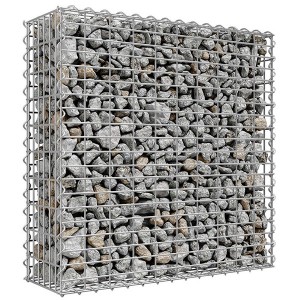

Wholesale China Welded Mesh Bird Cage Factories Pricelist – Welded Wire Mesh Gabion Box – Chongguan

Welded Mesh Gabion Boxes Sizes: Nominal Box sizes (m) No. of diaphragms (no.) Capacity per box (m3) Standard mesh sizes (mm) Standard wire diameter (mm) 1.0×1.0×0.5 Nil 0.50 50 x 50 75 x 75 100 x 50 100 x 100 Heavily Galvanised or Aluzinc coated wire 2.20, 2.50, 2.70, 3.00 4.00, 5.00 OR Polymer coated on Heavily Galvanised or Aluzinc coated wire 2.5/2.8, 2.7/3.0, 3.0/3.3, 4.0/4.3, 5.0/5.3 1.0×1.0×1.0 Nil 1.00 1.5×1.0×0.5 Nil 0.75 1.5×1.0×1.0 ...