Featured

Featured

-

Wholesale China Fence Company Products – V Beam Folds Welded Mesh Fence – Chongguan

It is also called “Curved Welded Mesh Fence”, “Bending Welded Mesh Fence”, “3D Triangle Welded Wire Mesh Fence”.Fence Panel with curves can make more stable ans sronger.Common color: green RAL6005, black RAL9005, white RAL9010PVC/PE coated surfacetreatment will with variety colors, it will make Welded Wire Mesh fence looks beautifull and anti-rust. 1.Panel sizes: Wire Diameter Mesh Size Length Height Fold No. 3.0mm4.0mm4.5mm5.0mm5.5mm6.0mm 50x2... -

Wholesale China Above Ground Pool Privacy Fence Factory Quotes – Bouble Wire Fence for Landscaping – Chongguan

The special specifications are available on request. Double Wire Fence Height × Width Panel mm Mesh Size mm Wire Diameter Post of Height mm Wire Dia mm Wire Dia mm Wire Dia mm 630×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1100 830×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1300 1030×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1500 1230×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1700 1430×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1900 ... -

Wholesale China Stainless Steel Filter Basket Company Products – Sintered Mesh of High Filter Efficiency – Chongguan

Raw Material: SS 316L, SS 304 Filter Rating Range: 0.5 Micron ~ 2000 Microns Filter Efficiency: > 99.99 % Number of Layers: 2 Layers ~ 20 Layers Operation Temperature: ≤ 816 ℃ Length: ≤ 1200 mm Width: ≤ 1000 mm Regular Size (Length*Width): 500 mm*500 mm,1000 mm*500 mm,1000 mm*1000 mm,1200 mm*1000 mm Thickness: 0.5 mm,1 mm,1.5 mm,2 mm,3 mm,5 mm or others 5-Layer Sintered Wire Mesh Sintering is a process that improves the characteristics of woven wire mesh by bonding the contact points of al... -

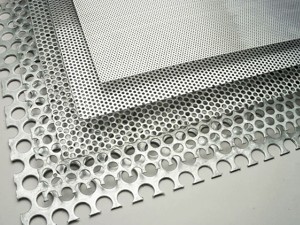

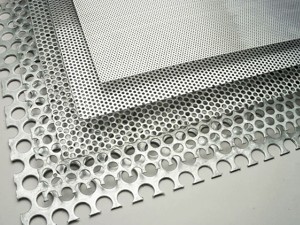

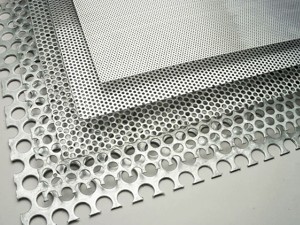

Wholesale China Stainless Steel Fly Screen Mesh Exporters Companies – Perforated Metal Mesh Sheet with Various Hole – Chongguan

Stainless Steel SUS 304 and 316, Galvanized Steel, Carbon Steel, Aluminum, and all types of metals. Round, square, long round, triangle, scale, diamond, oval, hexangular, slot etc. In general it is advisable to use a hole size larger than the material thickness. The closer the hole size and material thickness come to a 1 to 1 ratio, the more difficult and expensive the process is. Dependent on the material type, smaller hole size to material ratios can be achieved.The minimum diameter we can... -

Wholesale China Vinyl Coated Welded Wire Mesh Factory Quotes – Galvanized Welded Wire Mesh – Chongguan

Mesh Size Wire Gauge Diameter In mm In Inch BWG No. MM 6.4mm 1/4Inch BWG24-22 0.56mm- 0.71mm 9.5mm 3/8Inch BWG23-19 0.64mm – 1.07mm 12.7mm 1/2Inch BWG22-16 0.71mm – 1.65mm 15.9mm 5/8Inch BWG21-16 0.81mm – 1.65mm 19.1mm 3/4Inch BWG21-16 0.81mm – 1.85mm 25.4x 12.7mm 1 x 1/2Inch BWG21-16 0.81mm – 1.85mm 25.4mm 1Inch BWG21-14 0.81mm – 2.11mm 38.1mm 1 1/2Inch BWG19-14 ... -

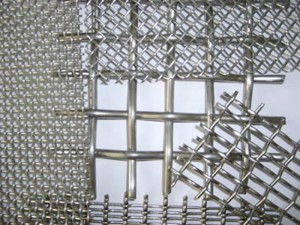

Wholesale China Heavy Duty Wire Mesh Panels Company Products – Crimped Wire Mesh For Industry – Chongguan

Black wire, spring steel wire, manganese steel wire and stainless steel wire. High tensile screen cloth is commonly used in heavy duty applications for scalping and sizing of rocks, aggregates, limestone, etc. They are weaved in sizes to suite most vibrating screens and available in: * High Tensile Steel—Abrasion resistance * Stainless Steel—Corrosion resistance * Monel, Brass, etc—General applications Crimped Wire Mesh is made through crimping mesh machine with pre-crimped ... -

Wholesale China Sintered Mesh Manufacturers Suppliers – Perforated Metal Mesh Sheet with Various Hole – Chongguan

Stainless Steel SUS 304 and 316, Galvanized Steel, Carbon Steel, Aluminum, and all types of metals. Round, square, long round, triangle, scale, diamond, oval, hexangular, slot etc. In general it is advisable to use a hole size larger than the material thickness. The closer the hole size and material thickness come to a 1 to 1 ratio, the more difficult and expensive the process is. Dependent on the material type, smaller hole size to material ratios can be achieved.The minimum diameter we can... -

Wholesale China Galvanised Welded Mesh Factories Pricelist – Welded Wire Mesh Panel Sheet – Chongguan

Low carbon steel wire(Q195,Q235), stainless steel wire • Black welded mesh panel (paint oil) without any surface treatment. • Electrical galvanized before/after welding (Electric galvanized welded mesh panel) • Hot deep galvanized before/after welding (hot deep galvanized welded mesh panel) • PVC coated welded mesh panel • PVC Powder painted mesh panel 1. Galvanized Welded Mesh Panels offer excellent characteristics such as corrosion resistance, oxidation resistance, acid resistance, alkali r... -

Wholesale China Gauge Wire Mesh Quotes Pricelist – UV Stabilized Plastic Insect Screen – Chongguan

Economical. The plastic insect screen is much cheaper than other material insect screen. Environmental friendly. All of the materials are recycled, it will not harm to the environments and people. Pure material. Our materials are all pure material, not the reborn plastic. UV stabilized. The material can resist the UV rays. Air movement. The square mesh of the insect screen permit the good movement of the air and water. The plastic insect screen can be used in the windows, doors, porches and p... -

Wholesale China Wire Mesh Air Filter Factories Pricelist – Galvanized Square Wire Mesh for Screening – Chongguan

Low carbon steel wire mesh is the most common plain steel alloy used in manufacturing industrial wire cloth screens due to its tensile strength and high impact resistance. Primarily comprised of iron, low carbon grades is q195. Low abrasion resistance and low corrosion resistance may limit usage in certain applications, however a wide variety of special protective coatings may be applied to improve resistance. Galvanizing (before or after) is the most economical way to protect against corrosi... -

Wholesale China Pleated Filter Factory Quotes – Pleated Filter of Large Filter Area – Chongguan

• Material: SS304, SS316, stainless steel woven wire mesh, stainless steel sintered fiber felt. • Filter rating: 0.1 micron to 100 micron. • Inner diameter: 28 mm, 40 mm. • Outer diameter: 64 mm, 70 mm. • Length: 10″, 20″, 30″, 40″. • Operating temperature: -200 – 600℃. • Low capital cost. • High porosity and good air permeability. • High dirt holding capacity. • Long service life time. • High temperature resistance. • Made entirely of SS304 or SS316, cleanable a... -

Wholesale China Stainless Steel Insect Mesh Factories Pricelist – Perforated Metal Mesh Sheet with Various Hole – Chongguan

Stainless Steel SUS 304 and 316, Galvanized Steel, Carbon Steel, Aluminum, and all types of metals. Round, square, long round, triangle, scale, diamond, oval, hexangular, slot etc. In general it is advisable to use a hole size larger than the material thickness. The closer the hole size and material thickness come to a 1 to 1 ratio, the more difficult and expensive the process is. Dependent on the material type, smaller hole size to material ratios can be achieved.The minimum diameter we can...