Featured

Featured

-

Wholesale China Plastic Netting Fence Company Products – Barbed Wire For Fencing System – Chongguan

Barbed Wire Specification Type Wire Gauge (BWG) Barb distance (cm) Barb length (cm) Electric GalvanizedBarbed wire ; Hot-dip Galvanized Barbed Wire 10# x12# 7.5-15 1.5-3 12# x12# 12# x14# 14# x 14# 14# x16# 16# x16# 16# x18# Pvc Coated Barbed Wire Before coating after coating 1.0mm-3.5mm 1.4mm-4.0mm BWG11#-20# BWG8#-17# SWG11#-20# SWG8#-17# PVC coating thickness: 0.4mm-1.0mmDifferent colors or length are available as customers` request Gauge of Approx... -

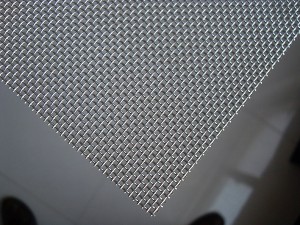

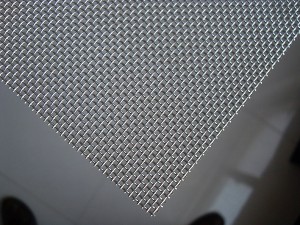

Wholesale China Wire Mesh Grill Factories Pricelist – Stainless Steel Woven Wire Mesh Netting CLoth – Chongguan

Material: SS 201, SS304, SS304L, SS316, SS316L, SS321, SS347,SS430, Monel. Type 304 Often referred to as “18-8″ (18% chromium, 8% nickel) T-304 is the basic stainless alloy most commonly utilized for wire cloth weaving. It withstands outdoor exposure without rusting and resists oxidation at an elevated temperature up to 1400 Degrees Fahrenheit. Type 304 L Type 304 L is very similar to T-304, the difference being the reduced carbon content for better weaving and secondary welding c... -

Wholesale China Stainless Wire Fence Quotes Pricelist – High Performance Stainless Steel Wire – Chongguan

1.Stainless steel lock wire – suitable for use in the automotive, aerospace and aeronautics industries and applications. 2.Stainless steel wire for crafts and hardware – suitable for using in jewelry, sculptures, welding, musical instruments and general hardware items such as screws, nails, rivets, key rings, staples, pins, carabiners and more. 3.Stainless steel wire for medical applications – this wire is used in orthodontics, acupuncture needles, microbiology, ophthalmology, surgery and eve... -

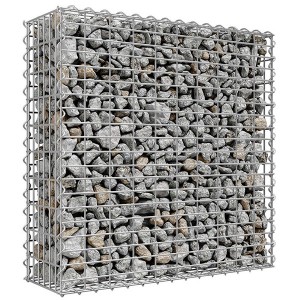

Wholesale China Welded Mesh Gabions Exporters Companies – Welded Wire Mesh Gabion Box – Chongguan

Welded Mesh Gabion Boxes Sizes: Nominal Box sizes (m) No. of diaphragms (no.) Capacity per box (m3) Standard mesh sizes (mm) Standard wire diameter (mm) 1.0×1.0×0.5 Nil 0.50 50 x 50 75 x 75 100 x 50 100 x 100 Heavily Galvanised or Aluzinc coated wire 2.20, 2.50, 2.70, 3.00 4.00, 5.00 OR Polymer coated on Heavily Galvanised or Aluzinc coated wire 2.5/2.8, 2.7/3.0, 3.0/3.3, 4.0/4.3, 5.0/5.3 1.0×1.0×1.0 Nil 1.00 1.5×1.0×0.5 Nil 0.75 1.5×1.0×1.0 ... -

Wholesale China Perforated Filter Tube Manufacturers Suppliers – Pleated Filter of Large Filter Area – Chongguan

• Material: SS304, SS316, stainless steel woven wire mesh, stainless steel sintered fiber felt. • Filter rating: 0.1 micron to 100 micron. • Inner diameter: 28 mm, 40 mm. • Outer diameter: 64 mm, 70 mm. • Length: 10″, 20″, 30″, 40″. • Operating temperature: -200 – 600℃. • Low capital cost. • High porosity and good air permeability. • High dirt holding capacity. • Long service life time. • High temperature resistance. • Made entirely of SS304 or SS316, cleanable a... -

Wholesale China Book Binding Wire Manufacturers Suppliers – Galvanized Wire Made In China – Chongguan

Electro galvanised wire (cold galvanized wire) is made by means of wire drawing followed by heat treatment and electro galvanizing. The galvanizing is made with mild steel or carbon steel wire in the plating bath, through the electric current unipolarity making zinc plating gradually on the surface. The galvanizing speed is slow to ensure a uniform coating, with thin thickness, usually only 3 to 15 microns. The outward appearance of electro galvanised steel wire is bright, the corrosion resis... -

Wholesale China Wire Mesh Price Factories Pricelist – Stainless Steel Woven Wire Mesh Netting CLoth – Chongguan

Material: SS 201, SS304, SS304L, SS316, SS316L, SS321, SS347,SS430, Monel. Type 304 Often referred to as “18-8″ (18% chromium, 8% nickel) T-304 is the basic stainless alloy most commonly utilized for wire cloth weaving. It withstands outdoor exposure without rusting and resists oxidation at an elevated temperature up to 1400 Degrees Fahrenheit. Type 304 L Type 304 L is very similar to T-304, the difference being the reduced carbon content for better weaving and secondary welding c... -

Wholesale China Framed Wire Mesh Panels Company Products – Most Durable Aluminium Window Screen – Chongguan

Aluminum window screen is made of Al-Mg alloy wire in plain weaving. Screens made from aluminum mesh is one of the sturdiest and most durable screens available. They have a long lifespan and will protect you from different weather conditions, including rain, strong winds, and even hail in some cases. Aluminum mesh screens are resistant to abrasion, corrosion, and rust, making them a great screen choice for nearly any environment. Aluminum wire window screens also will not sag or rust, extend... -

Wholesale China Hydraulic Strainer Filter Factory Quotes – Pleated Filter of Large Filter Area – Chongguan

• Material: SS304, SS316, stainless steel woven wire mesh, stainless steel sintered fiber felt. • Filter rating: 0.1 micron to 100 micron. • Inner diameter: 28 mm, 40 mm. • Outer diameter: 64 mm, 70 mm. • Length: 10″, 20″, 30″, 40″. • Operating temperature: -200 – 600℃. • Low capital cost. • High porosity and good air permeability. • High dirt holding capacity. • Long service life time. • High temperature resistance. • Made entirely of SS304 or SS316, cleanable a... -

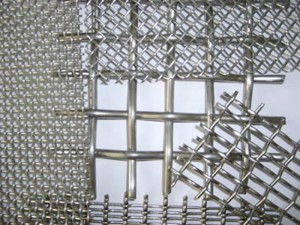

Wholesale China Steel Wire Mesh Panels Manufacturers Suppliers – Crimped Wire Mesh For Industry – Chongguan

Black wire, spring steel wire, manganese steel wire and stainless steel wire. High tensile screen cloth is commonly used in heavy duty applications for scalping and sizing of rocks, aggregates, limestone, etc. They are weaved in sizes to suite most vibrating screens and available in: * High Tensile Steel—Abrasion resistance * Stainless Steel—Corrosion resistance * Monel, Brass, etc—General applications Crimped Wire Mesh is made through crimping mesh machine with pre-crimped ... -

Wholesale China Aluminium Mesh Windows Exporters Companies – Steel Grating For Stairs and Walkway – Chongguan

As producing method: 1.Welded steel grating 2.Press-locked grating 3.Swage-locked grating 4.Riveted grating 5.Offshore Platform Reinforced Floor Grating As material: 1.Aluminum grating 2.Stainless steel grating 3.Expanded Steel Grating 4.Fiberglass grating No. Item Description 1 Bearing Bar Size 25×3, 25×4, 25×4.5, 25×5, 30×3, 30×4, 30×4.5, 30×5, 32×5, 40×5, 50×5, 65×5, 75×6, 75×10—100x10mm etc. I bar: 25x5x3... -

Wholesale China Black Welded Wire Manufacturers Suppliers – Galvanized Wire Made In China – Chongguan

Electro galvanised wire (cold galvanized wire) is made by means of wire drawing followed by heat treatment and electro galvanizing. The galvanizing is made with mild steel or carbon steel wire in the plating bath, through the electric current unipolarity making zinc plating gradually on the surface. The galvanizing speed is slow to ensure a uniform coating, with thin thickness, usually only 3 to 15 microns. The outward appearance of electro galvanised steel wire is bright, the corrosion resis...