Featured

Featured

-

Wholesale China Coated Wire Mesh Exporters Companies – Factory Supply Brass And Copper Wire Mesh – Chongguan

Brass wire mesh is a woven wire mesh where warp and weft (woof / filling) wires are interlaced at right angles. In other words, each warp wire and each weft wire pass over one, two or other amounts of wires, and then under the next one, two or other amounts of wires. Brass is an alloy that is comprised of copper and zinc, and, like copper, brass is soft and malleable and is attacked by ammonia and similar salts. As a wire mesh, the most commonly available brass woven wire mesh is referred to ... -

Wholesale China Fence For Sale Factory Quotes – Bouble Wire Fence for Landscaping – Chongguan

The special specifications are available on request. Double Wire Fence Height × Width Panel mm Mesh Size mm Wire Diameter Post of Height mm Wire Dia mm Wire Dia mm Wire Dia mm 630×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1100 830×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1300 1030×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1500 1230×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1700 1430×2500 50×200 8×2 + 6 6×2 + 5 6×2 + 4 1900 ... -

Wholesale China Galvanized Wire Company Products – Galvanized Wire Made In China – Chongguan

Electro galvanised wire (cold galvanized wire) is made by means of wire drawing followed by heat treatment and electro galvanizing. The galvanizing is made with mild steel or carbon steel wire in the plating bath, through the electric current unipolarity making zinc plating gradually on the surface. The galvanizing speed is slow to ensure a uniform coating, with thin thickness, usually only 3 to 15 microns. The outward appearance of electro galvanised steel wire is bright, the corrosion resis... -

Wholesale China Split Rail Fence For Sale Company Products – High Security 358 Mesh Fence – Chongguan

Panels Post Fence Panel Size Post Size Post Height Total Number of Fixings Height Height/Width Length/Width/Thickness Inters- 1 clamp Corners-2 clamp m mm mm mm 2.0 2007 × 2515 60×60×2.5mm 2700 7 14 2.4 2400 × 2515 60×60×2.5mm 3100 9 18 3.0 2997 × 2515 80×80×2.5mm 3800 11 22 3.3 3302 × 2515 80×80×2.5mm 4200 12 24 3.6 3607 × 2515 100×60×3mm 4500 13 26 3.6 3607 × 2515 100×1... -

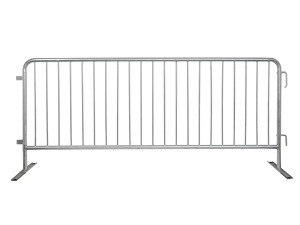

Wholesale China Mesh Fence Netting Factories Pricelist – Barricade for Pedestrian and Vehicular Traffic – Chongguan

Crowd control barriers (also referred to as crowd control barricades, with some versions called a french barrier or bike rack in the USA), are commonly used at many public events. Crowd control barriers have been designed for use at events that need to accommodate for a larger crowd. They are designed to physically discourage transgression and encourage directional order and crowd control. Their flat feet feature (to prevent trip hazard) provides a quick and efficient solution in any situatio... -

Wholesale China Quick Link Wire Quotes Pricelist – Black Annealed Low Carbon Steel Wire – Chongguan

The annealing process is used to achieve a finished product from low carbon steel wire. Annealing involves heating the wire to a specific temperature before cooling it at a prescribed rate in order to achieve the desired result.Annealing is used with the goal of increasing the ductility of the wire and reducing the hardness. This allows the wire to be flexible while still remaining durable. With these properties, annealed wire is self-tying and can stay in place when wrapped around itself. M... -

Wholesale China 358 Mesh Fence Manufacturers Suppliers – Razor Barbed Wire For Security Fence – Chongguan

Razor Blade Type and Specification Reference number Thickness/mm Wire Dia/mm Barb length/mm Barb width/mm Barb spacing/mm BTO-10 0.5±0.05 2.5±0.1 10±1 13±1 26±1 BTO-12 0.5±0.05 2.5±0.1 12±1 15±1 26±1 BTO-18 0.5±0.05 2.5±0.1 18±1 15±1 33±1 BTO-22 0.5±0.05 2.5±0.1 22±1 15±1 34±1 BTO-28 0.5±0.05 2.5 28 15 45±1 BTO-30 0.5±0.05 2.5 30 18 45±1 CBT-60 0.5±0.05 2.5±0.1 60±2 32±1 100±2 CBT-65 0.5±0.05 2.5±0.1 65±2 21±1 100±2 Outer diameter No. of loops Standard len... -

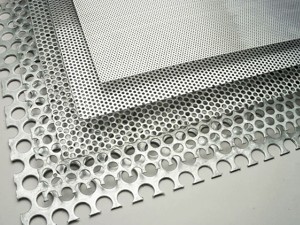

Wholesale China Stainless Steel Mesh Bbq Exporters Companies – Perforated Metal Mesh Sheet with Various Hole – Chongguan

Stainless Steel SUS 304 and 316, Galvanized Steel, Carbon Steel, Aluminum, and all types of metals. Round, square, long round, triangle, scale, diamond, oval, hexangular, slot etc. In general it is advisable to use a hole size larger than the material thickness. The closer the hole size and material thickness come to a 1 to 1 ratio, the more difficult and expensive the process is. Dependent on the material type, smaller hole size to material ratios can be achieved.The minimum diameter we can... -

Wholesale China Wirecrafters Wire Fencing Manufacturers Suppliers – Black Annealed Low Carbon Steel Wire – Chongguan

The annealing process is used to achieve a finished product from low carbon steel wire. Annealing involves heating the wire to a specific temperature before cooling it at a prescribed rate in order to achieve the desired result.Annealing is used with the goal of increasing the ductility of the wire and reducing the hardness. This allows the wire to be flexible while still remaining durable. With these properties, annealed wire is self-tying and can stay in place when wrapped around itself. M... -

Wholesale China Wire Mesh Screen Quotes Pricelist – Factory Supply Brass And Copper Wire Mesh – Chongguan

Brass wire mesh is a woven wire mesh where warp and weft (woof / filling) wires are interlaced at right angles. In other words, each warp wire and each weft wire pass over one, two or other amounts of wires, and then under the next one, two or other amounts of wires. Brass is an alloy that is comprised of copper and zinc, and, like copper, brass is soft and malleable and is attacked by ammonia and similar salts. As a wire mesh, the most commonly available brass woven wire mesh is referred to ... -

Wholesale China Wire Mesh Company Exporters Companies – UV Stabilized Plastic Insect Screen – Chongguan

Economical. The plastic insect screen is much cheaper than other material insect screen. Environmental friendly. All of the materials are recycled, it will not harm to the environments and people. Pure material. Our materials are all pure material, not the reborn plastic. UV stabilized. The material can resist the UV rays. Air movement. The square mesh of the insect screen permit the good movement of the air and water. The plastic insect screen can be used in the windows, doors, porches and p... -

Wholesale China Galvanized Welded Wire Mesh Panels Factory Quotes – Galvanized Welded Wire Mesh – Chongguan

Mesh Size Wire Gauge Diameter In mm In Inch BWG No. MM 6.4mm 1/4Inch BWG24-22 0.56mm- 0.71mm 9.5mm 3/8Inch BWG23-19 0.64mm – 1.07mm 12.7mm 1/2Inch BWG22-16 0.71mm – 1.65mm 15.9mm 5/8Inch BWG21-16 0.81mm – 1.65mm 19.1mm 3/4Inch BWG21-16 0.81mm – 1.85mm 25.4x 12.7mm 1 x 1/2Inch BWG21-16 0.81mm – 1.85mm 25.4mm 1Inch BWG21-14 0.81mm – 2.11mm 38.1mm 1 1/2Inch BWG19-14 ...