Featured

Featured

-

Wholesale China Wire For Fencing Factories Pricelist – Black Annealed Low Carbon Steel Wire – Chongguan

The annealing process is used to achieve a finished product from low carbon steel wire. Annealing involves heating the wire to a specific temperature before cooling it at a prescribed rate in order to achieve the desired result.Annealing is used with the goal of increasing the ductility of the wire and reducing the hardness. This allows the wire to be flexible while still remaining durable. With these properties, annealed wire is self-tying and can stay in place when wrapped around itself. M... -

Wholesale China Binding Wire Rate Company Products – High Performance Stainless Steel Wire – Chongguan

1.Stainless steel lock wire – suitable for use in the automotive, aerospace and aeronautics industries and applications. 2.Stainless steel wire for crafts and hardware – suitable for using in jewelry, sculptures, welding, musical instruments and general hardware items such as screws, nails, rivets, key rings, staples, pins, carabiners and more. 3.Stainless steel wire for medical applications – this wire is used in orthodontics, acupuncture needles, microbiology, ophthalmology, surgery and eve... -

Wholesale China Quick Link Wire Manufacturers Suppliers – Anti-corrosion PVC Coated Metal Wire – Chongguan

PVC / plastic coated steel wire is processed with coating a layer of polyvinyl chloride or polyethylene on the surface of the core wires ( annealed wire, galvanized wire, stainless steel wire, Galfan wires, etc). The coating layer firmly bonded to the wire render the features of anti-aging, anti-corrosion, anti-cracking, long life and other characteristics. Materials before PVC coating: steel wire, galvanized wire, redrawing wire, annealed wire, etc. Surface: plastic covering or plastic coat... -

Wholesale China Galvanized Welded Wire Mesh Exporters Companies – Welded Wire Mesh Panel Sheet – Chongguan

Low carbon steel wire(Q195,Q235), stainless steel wire • Black welded mesh panel (paint oil) without any surface treatment. • Electrical galvanized before/after welding (Electric galvanized welded mesh panel) • Hot deep galvanized before/after welding (hot deep galvanized welded mesh panel) • PVC coated welded mesh panel • PVC Powder painted mesh panel 1. Galvanized Welded Mesh Panels offer excellent characteristics such as corrosion resistance, oxidation resistance, acid resistance, alkali r... -

Wholesale China Stainless Steel Grill Mesh Factories Pricelist – Steel Grating For Stairs and Walkway – Chongguan

As producing method: 1.Welded steel grating 2.Press-locked grating 3.Swage-locked grating 4.Riveted grating 5.Offshore Platform Reinforced Floor Grating As material: 1.Aluminum grating 2.Stainless steel grating 3.Expanded Steel Grating 4.Fiberglass grating No. Item Description 1 Bearing Bar Size 25×3, 25×4, 25×4.5, 25×5, 30×3, 30×4, 30×4.5, 30×5, 32×5, 40×5, 50×5, 65×5, 75×6, 75×10—100x10mm etc. I bar: 25x5x3... -

Wholesale China Welded Wire Mesh 3315 Factory Quotes – Stainless Steel Welded Wire Mesh – Chongguan

All the spacing between wires are controlled by an automatic mechanism of high reliability. So the welded wire mesh size like wire diameters, opening size and panel weight are all available in a wide range. According to its size it can be made into panels and rolls. The materials and size can be chosen from a wide range. Materials: SS201, SS202, SS302, SS304, SS304L, SS316, SS316 and so on. Wire diameter: from 0.6 mm to 2.6 mm. Mesh opening: mini 6.4 mm and max 200 mm is available. Panels: 3 ... -

Wholesale China Double Loop Wire Quotes Pricelist – Galvanized Wire Made In China – Chongguan

Electro galvanised wire (cold galvanized wire) is made by means of wire drawing followed by heat treatment and electro galvanizing. The galvanizing is made with mild steel or carbon steel wire in the plating bath, through the electric current unipolarity making zinc plating gradually on the surface. The galvanizing speed is slow to ensure a uniform coating, with thin thickness, usually only 3 to 15 microns. The outward appearance of electro galvanised steel wire is bright, the corrosion resis... -

Wholesale China Welded Wire Mesh 2214 Factory Quotes – Welded Wire Mesh Panel Sheet – Chongguan

Low carbon steel wire(Q195,Q235), stainless steel wire • Black welded mesh panel (paint oil) without any surface treatment. • Electrical galvanized before/after welding (Electric galvanized welded mesh panel) • Hot deep galvanized before/after welding (hot deep galvanized welded mesh panel) • PVC coated welded mesh panel • PVC Powder painted mesh panel 1. Galvanized Welded Mesh Panels offer excellent characteristics such as corrosion resistance, oxidation resistance, acid resistance, alkali r... -

Wholesale China Sintered Brass Filter Factory Quotes – Sintered Mesh of High Filter Efficiency – Chongguan

Raw Material: SS 316L, SS 304 Filter Rating Range: 0.5 Micron ~ 2000 Microns Filter Efficiency: > 99.99 % Number of Layers: 2 Layers ~ 20 Layers Operation Temperature: ≤ 816 ℃ Length: ≤ 1200 mm Width: ≤ 1000 mm Regular Size (Length*Width): 500 mm*500 mm,1000 mm*500 mm,1000 mm*1000 mm,1200 mm*1000 mm Thickness: 0.5 mm,1 mm,1.5 mm,2 mm,3 mm,5 mm or others 5-Layer Sintered Wire Mesh Sintering is a process that improves the characteristics of woven wire mesh by bonding the contact points of al... -

Wholesale China Cut Wire Factories Pricelist – Anti-corrosion PVC Coated Metal Wire – Chongguan

PVC / plastic coated steel wire is processed with coating a layer of polyvinyl chloride or polyethylene on the surface of the core wires ( annealed wire, galvanized wire, stainless steel wire, Galfan wires, etc). The coating layer firmly bonded to the wire render the features of anti-aging, anti-corrosion, anti-cracking, long life and other characteristics. Materials before PVC coating: steel wire, galvanized wire, redrawing wire, annealed wire, etc. Surface: plastic covering or plastic coat... -

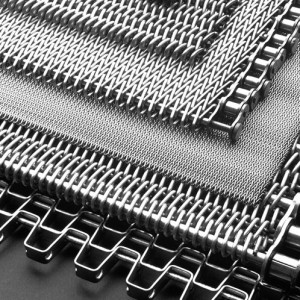

Wholesale China Galvanised Steel Mesh Company Products – Stainless Steel Wire Mesh Conveyor Belt – Chongguan

Flat wire conveyor belts have two types according to its loading capacity. One is Standard Duty General Purpose flat wire belt, another is Heavy Duty Belt. All flat wire belting offers a smooth conveying surface and a maximum open area for free air flow or water drainage. They are easy to clean and are extremely sanitary, especially when manufactured with high quality clinched edges. Clinched-edge treatment of these belts results in a number of additional user benefits including keeping the t... -

Wholesale China Quick Link Wire Exporters Companies – Black Annealed Low Carbon Steel Wire – Chongguan

The annealing process is used to achieve a finished product from low carbon steel wire. Annealing involves heating the wire to a specific temperature before cooling it at a prescribed rate in order to achieve the desired result.Annealing is used with the goal of increasing the ductility of the wire and reducing the hardness. This allows the wire to be flexible while still remaining durable. With these properties, annealed wire is self-tying and can stay in place when wrapped around itself. M...