Featured

Featured

-

Wholesale China Heavy Gauge Wire Mesh Quotes Pricelist – Galvanized Square Wire Mesh for Screening – Chongguan

Low carbon steel wire mesh is the most common plain steel alloy used in manufacturing industrial wire cloth screens due to its tensile strength and high impact resistance. Primarily comprised of iron, low carbon grades is q195. Low abrasion resistance and low corrosion resistance may limit usage in certain applications, however a wide variety of special protective coatings may be applied to improve resistance. Galvanizing (before or after) is the most economical way to protect against corrosi... -

Wholesale China Hydraulic Strainer Filter Manufacturers Suppliers – Pleated Filter of Large Filter Area – Chongguan

• Material: SS304, SS316, stainless steel woven wire mesh, stainless steel sintered fiber felt. • Filter rating: 0.1 micron to 100 micron. • Inner diameter: 28 mm, 40 mm. • Outer diameter: 64 mm, 70 mm. • Length: 10″, 20″, 30″, 40″. • Operating temperature: -200 – 600℃. • Low capital cost. • High porosity and good air permeability. • High dirt holding capacity. • Long service life time. • High temperature resistance. • Made entirely of SS304 or SS316, cleanable a... -

Wholesale China Welded Mesh Wire Exporters Companies – Welded Wire Mesh Panel Sheet – Chongguan

Low carbon steel wire(Q195,Q235), stainless steel wire • Black welded mesh panel (paint oil) without any surface treatment. • Electrical galvanized before/after welding (Electric galvanized welded mesh panel) • Hot deep galvanized before/after welding (hot deep galvanized welded mesh panel) • PVC coated welded mesh panel • PVC Powder painted mesh panel 1. Galvanized Welded Mesh Panels offer excellent characteristics such as corrosion resistance, oxidation resistance, acid resistance, alkali r... -

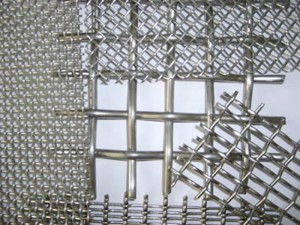

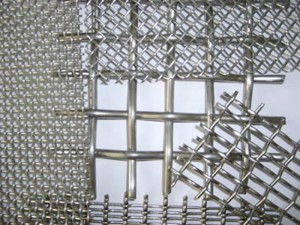

Wholesale China Crimped Wire Mesh Factories Pricelist – Crimped Wire Mesh For Industry – Chongguan

Black wire, spring steel wire, manganese steel wire and stainless steel wire. High tensile screen cloth is commonly used in heavy duty applications for scalping and sizing of rocks, aggregates, limestone, etc. They are weaved in sizes to suite most vibrating screens and available in: * High Tensile Steel—Abrasion resistance * Stainless Steel—Corrosion resistance * Monel, Brass, etc—General applications Crimped Wire Mesh is made through crimping mesh machine with pre-crimped ... -

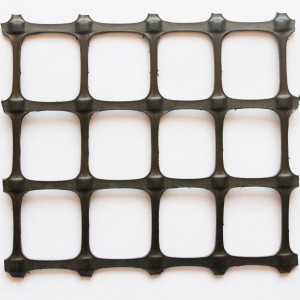

Wholesale China Barbeque Wire Mesh Quotes Pricelist – High Strength Biaxial Plastic Geogrid – Chongguan

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine. Index Properties Test Method Unit GG1515 GG2020 GG3030 GG4040 MD TD MD TD MD TD MD TD Polymer – – PP PP PP PP Minimum Carbon Black ASTM D 4218 % 2 2 2 2 Tensile Strength@ 2% Strain ASTM D 6637 Kn/m 5 5 7 7 10.5 10.5 14 14 Tensile Strength@ 5% Strain ASTM D 6637 Kn/m 7 7 14 14 21 21 28 2... -

Wholesale China Cheap Wire Mesh Exporters Companies – Factory Supply Brass And Copper Wire Mesh – Chongguan

Brass wire mesh is a woven wire mesh where warp and weft (woof / filling) wires are interlaced at right angles. In other words, each warp wire and each weft wire pass over one, two or other amounts of wires, and then under the next one, two or other amounts of wires. Brass is an alloy that is comprised of copper and zinc, and, like copper, brass is soft and malleable and is attacked by ammonia and similar salts. As a wire mesh, the most commonly available brass woven wire mesh is referred to ... -

Wholesale China Welded Mesh Suppliers Company Products – Welded Wire Mesh Panel Sheet – Chongguan

Low carbon steel wire(Q195,Q235), stainless steel wire • Black welded mesh panel (paint oil) without any surface treatment. • Electrical galvanized before/after welding (Electric galvanized welded mesh panel) • Hot deep galvanized before/after welding (hot deep galvanized welded mesh panel) • PVC coated welded mesh panel • PVC Powder painted mesh panel 1. Galvanized Welded Mesh Panels offer excellent characteristics such as corrosion resistance, oxidation resistance, acid resistance, alkali r... -

Wholesale China Copper Wire Coil Company Products – Black Annealed Low Carbon Steel Wire – Chongguan

The annealing process is used to achieve a finished product from low carbon steel wire. Annealing involves heating the wire to a specific temperature before cooling it at a prescribed rate in order to achieve the desired result.Annealing is used with the goal of increasing the ductility of the wire and reducing the hardness. This allows the wire to be flexible while still remaining durable. With these properties, annealed wire is self-tying and can stay in place when wrapped around itself. M... -

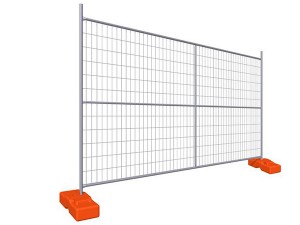

Wholesale China Fence For Pools Exporters Companies – Temporary Fence for Public Security – Chongguan

It is also Called construction Mobile fence/Temporary Fence/portable construction fence/portable movable fencing Temporary fence services and height safety services are crucial for industries where injury is a constant risk. Employee and public safety is a priority for those in: mining, construction, civil, residential, government, industrial, commercial, maintenance or special events. Detail of Temporary Fence Panel for Australia and New Zealand Panel Size(mm) 1800(H)*2100(L),1800(H)*2... -

Wholesale China Black Wire Mesh Exporters Companies – Crimped Wire Mesh For Industry – Chongguan

Black wire, spring steel wire, manganese steel wire and stainless steel wire. High tensile screen cloth is commonly used in heavy duty applications for scalping and sizing of rocks, aggregates, limestone, etc. They are weaved in sizes to suite most vibrating screens and available in: * High Tensile Steel—Abrasion resistance * Stainless Steel—Corrosion resistance * Monel, Brass, etc—General applications Crimped Wire Mesh is made through crimping mesh machine with pre-crimped ... -

Wholesale China Ss Welded Mesh Exporters Companies – Welded Wire Mesh Panel Sheet – Chongguan

Low carbon steel wire(Q195,Q235), stainless steel wire • Black welded mesh panel (paint oil) without any surface treatment. • Electrical galvanized before/after welding (Electric galvanized welded mesh panel) • Hot deep galvanized before/after welding (hot deep galvanized welded mesh panel) • PVC coated welded mesh panel • PVC Powder painted mesh panel 1. Galvanized Welded Mesh Panels offer excellent characteristics such as corrosion resistance, oxidation resistance, acid resistance, alkali r... -

Wholesale China Binding Wire Price Quotes Pricelist – Black Annealed Low Carbon Steel Wire – Chongguan

The annealing process is used to achieve a finished product from low carbon steel wire. Annealing involves heating the wire to a specific temperature before cooling it at a prescribed rate in order to achieve the desired result.Annealing is used with the goal of increasing the ductility of the wire and reducing the hardness. This allows the wire to be flexible while still remaining durable. With these properties, annealed wire is self-tying and can stay in place when wrapped around itself. M...